Petro-chemical industry Application

Contact us by phone +49 3523 73146 or email

So that no sparks ignite

Cold cuts for refurbishment activities on refineries

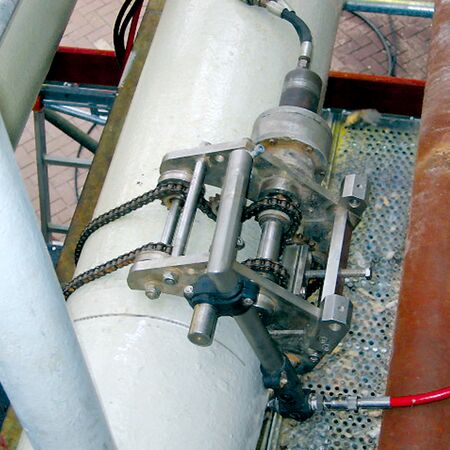

In petrochemical and chemical operations, there is frequently an explosion risk with cutting and separating activities. Therefore, the cold-cutting technology is used on plants for inspections, changes and the dismantling of plant parts. With our environmentally friendly water-jet cutting technology, we are able to handle repairs, revisions and dismantling of industrial plants.

Your advantages:

- Safe cutting using remote control for the cutting technology

- Economic advantages from cold cuts using a maximum-pressure water jet and abrasive (cutting sand)

- Non-hazardous working in sensitive explosive atmosphere sites

- Cutting activities on all structures and through all materials; also through "sandwich materials"

Rely on our expertise with repair measures on chemical/petrochemical plants We can offer you sophisticated engineering solutions, in order to quickly and safely perform virtually all conceivable refurbishment and maintenance measures on industrial plants using cold cutting.

Apply cold-cutting technology universally

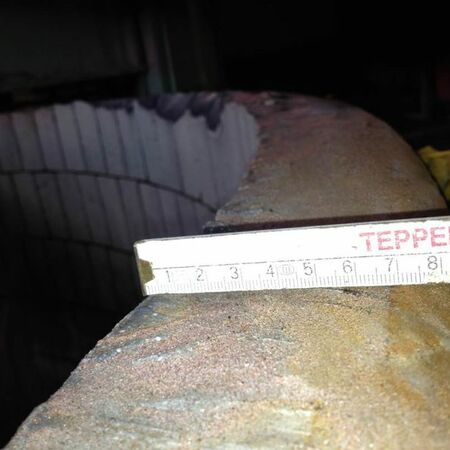

Cold cuts are the optimum procedure for realising cutting and separating activities on refineries and similar plants. With cold cutting, it neither depends on heat generation nor a change to the material structure. This is particularly advantageous, if new components are to be welded onto the cut surfaces.

We also use the abrasive water-jet cutting for the preparation of welding seams of pipelines with and without a bevel. This technology is used a several points of industrial structures. These include, e.g.:

- Tank shells/tank walls

- Single and double tank bases

- Tank roofs of solid-roof tanks

- Floating roofs of floating-roof tanks

- Storage containers of any type

- Pipelines and components of virtually all diameters

- Dismantling of columns

Cutting procedures for explosive atmospheres

For pipelines that are filled with explosive gases or liquids, cold cutting is an ideal solution. During the course of this procedure, no hot sparks are created while working, so that a safe work process is guaranteed. This way, necessary building measures can also be completed during the running operation.

On refineries, you can also use suspension-jet water cutting for processing containers, columns and torch lines with thick walls. With double/double-layer tank bases, the water-jet cutting also allows only the top tank base to be separated, whereby the bottom tank base is retained.

Take advantage of the use of cold-cutting technology on industrial plants

In the field of cold cutting, we have more than 15 years of experience and therefore offer optimum solutions for the reliable execution of your orders. We will be pleased to develop these solutions jointly with you in a detailed consultation.